-

As part of the Edelmann Group – The Packaging Experience, our group had the opportunity to see premium packaging not merely as a “box,” but as a complete product in which design, structural engineering, printing technologies, and quality control are closely interconnected.

The visit began with an introductory presentation about the Edelmann Group, focusing on how the company collaborates with clients and delivers tailor-made solutions for a wide range of brands. Particular emphasis was placed on process consistency and repeatability, ensuring that an approved concept can be reliably reproduced at an industrial scale without compromising quality.

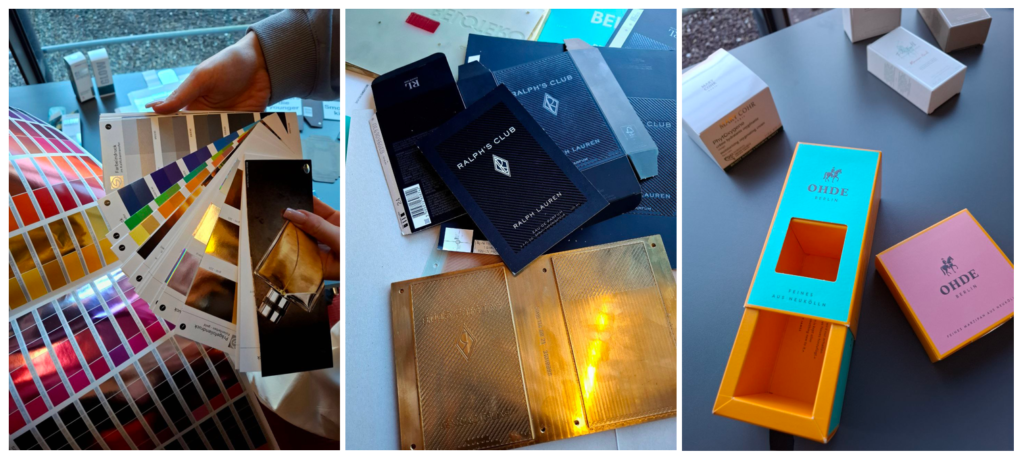

Following the introduction, we explored a broad selection of packaging samples and materials. We examined different structural formats, including solutions with inserts and inlays, and reviewed multiple finishing options such as embossing/debossing, special varnishes, metallic effects, foil stamping, and a wide range of color variations. Color and finishing swatches helped demonstrate how visual and tactile effects are selected and standardized for premium products.

The most valuable part of the experience was observing the production workflow in a real manufacturing environment, from early development through to production readiness. The tour illustrated the complete end-to-end process: structural packaging design (including dielines, folds, tolerances, and custom geometries), prototyping and testing (assembly checks, product fit, durability, and opening/closing functionality), graphic design preparation and prepress stages, and finally sample approval as a formal quality checkpoint prior to industrial production.

During the plant tour, we observed a range of machines used for embossing and specialty effects, metallic finishing, and various printing technologies. We also learned how internal logistics supports production efficiency through the coordinated transport and handling of semi-finished products between different production areas. A particularly interesting stage was the in-house development of custom stencils and cutting dies within a dedicated department, enabling precise and repeatable cutting and forming of non-standard packaging shapes.

Overall, The Packaging Experience demonstrated that packaging is the result of a controlled and methodical process in which design and technology evolve together. Prototyping, approval stages, and tooling—such as dies, stencils, and cutting forms—play a critical role in transforming concepts into stable, high-quality mass production.