-

Educational Visit to MUHR & SÖHNE GmbH & Co. KG: Industrial Manufacturing in Practice

11. Dezember 2025

As part of the DAAD-funded PACK IT academic mobility program, which aims to connect academic education with real industrial practice in the field of packaging, a study visit was organized to MUHR & SÖHNE GmbH & Co. KG in Ohrdruf, Germany. The visit provided students with valuable insight into specialized metal packaging solutions designed for demanding industrial applications and regulated goods.

MUHR & SÖHNE GmbH & Co. KG specializes in the production of metal packaging for dangerous goods and serves a wide range of industries, including chemicals, paints and coatings, oil, and pharmaceuticals. The company’s product portfolio includes containers with capacities ranging from 1 to 250 liters, featuring advanced closure and sealing systems that ensure safe storage, transport, and compliance with international ADR and UN transport regulations.

During the visit, a detailed presentation was delivered by Technical Director Roland Scheele, who outlined the company’s profile, core business areas, production capabilities, and extensive product range. Particular attention was given to the manufacturing technologies employed, as well as to strict adherence to international quality, safety, and certification standards. The presentation highlighted how technical precision, regulatory compliance, and innovative engineering solutions are combined to meet the high safety requirements and testing of dangerous goods packaging.

Following the presentation, a guided tour of the production facilities was organized by the company’s staff. During the tour, participants observed the operation of modern production lines and the manufacturing processes for various types of metal packaging products. The visit allowed for a closer look at how individual production stages are coordinated to ensure efficiency, precision, and consistent product quality.

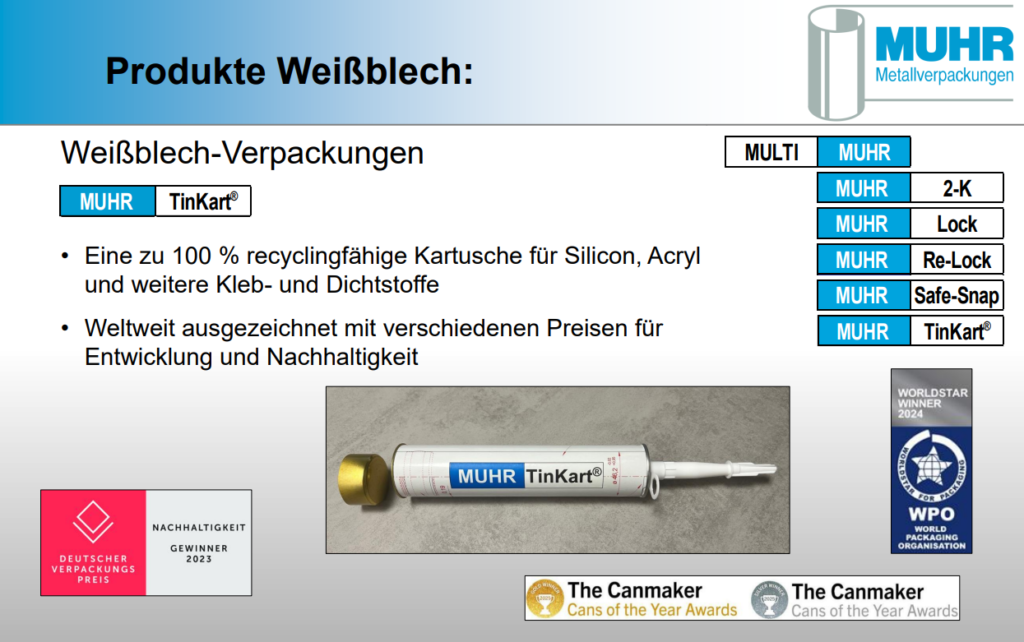

MUHR & SÖHNE’s industrial operations are supported by highly qualified personnel, a high degree of production automation, and the continuous implementation of innovative technologies. One of the most recent technological developments presented during the visit was the production of steel cartridges for silicone, acrylics, and sealants. This type of packaging offers high mechanical strength, reliable sealing performance, and full recyclability, making it a sustainable alternative to conventional solutions. The example clearly demonstrated how metal packaging can support circular economy principles while meeting the strict technical and safety requirements of industrial applications.

Students specializing in Packaging, Automation, and Software Engineering gained valuable practical insights into production automation, industrial packaging systems, and the role of software in modern manufacturing environments. The visit clearly demonstrated how different technical disciplines interact within a single production process to ensure efficiency, safety, and product reliability.

Particular attention during the tour was given to advanced plasma and laser welding technologies, which ensure absolute airtightness of steel cartridge seams. In contrast to traditional plastic packaging, steel cartridges are capable of withstanding significantly higher internal pressure, a critical requirement for high-viscosity sealants and chemically aggressive substances.

In addition, students observed integrated quality control systems in operation, where each individual product undergoes automated leak testing using compressed air and high-precision sensors. These systems enable MUHR & SÖHNE GmbH & Co. KG to guarantee product safety and reliability during storage and transportation, fully complying with strict UN international standards for the handling of dangerous goods.

In addition, students observed integrated quality control systems in operation, where each individual product undergoes automated leak testing using compressed air and high-precision sensors. These systems enable MUHR & SÖHNE GmbH & Co. KG to guarantee product safety and reliability during storage and transportation, fully complying with strict UN international standards for the handling of dangerous goods.Beyond its technical advantages, the adoption of steel packaging forms part of a broader global strategy focused on sustainable development and the circular economy. As steel can be recycled indefinitely without any loss of its physical properties, the transition from single-use plastics to metal cartridges contributes significantly to reducing the carbon footprint of the chemical and construction-related industries.

For students specializing in Packaging, the visit provided a clear understanding of how material selection, structural design, and closure systems directly influence product safety, regulatory compliance, and sustainability. At the same time, students in IT and Automation gained valuable insights into how Manufacturing Execution System (MES) software synchronizes raw material supply chains with robotic production units. This digital integration enables real-time monitoring, minimizes scrap metal waste, and optimizes overall energy consumption across the plant. Together, these observations demonstrated how packaging engineering, digitalization, and automation are integrated to create efficient, safe, and environmentally responsible industrial systems.