-

Educational Visit to Ardagh Group in Germany: Experience and Insights within the PACK IT Program

8. Dezember 2025

Within the framework of the DAAD-funded PACK IT mobility program, Ukrainian students, together with students of the Department of Packaging and Management at Berlin University of Applied Sciences (BHT), participated in a series of educational visits to leading German industrial enterprises. These visits were designed to connect theoretical knowledge with real industrial practice and to explore packaging solutions across different materials, technologies, and production scales. One of the key excursions within this program was a visit to Ardagh Group, a global leader in sustainable metal and glass packaging.

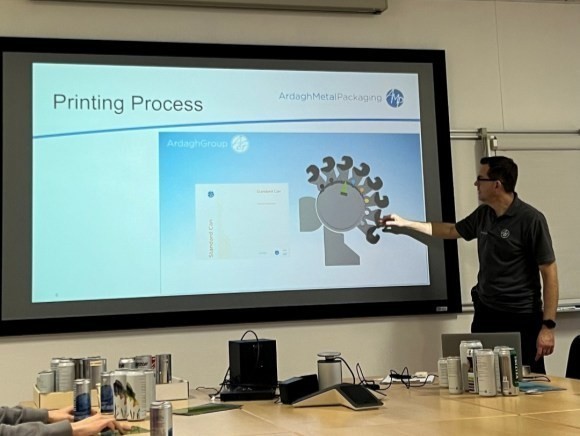

Within the framework of the DAAD-funded PACK IT mobility program, Ukrainian students, together with students of the Department of Packaging and Management at Berlin University of Applied Sciences (BHT), participated in a series of educational visits to leading German industrial enterprises. These visits were designed to connect theoretical knowledge with real industrial practice and to explore packaging solutions across different materials, technologies, and production scales. One of the key excursions within this program was a visit to Ardagh Group, a global leader in sustainable metal and glass packaging.Students visited the Ardagh Group production facilities in Germany, where they attended expert presentations and explored the manufacturing environment firsthand. The visit successfully combined theoretical insights with practical observation, allowing students to gain a deeper understanding of how a modern industrial enterprise operates. Overall, the excursion proved to be highly informative and left a strong positive impression.

The main purpose of the visit was to become familiar with the activities of Ardagh Group, its organizational structure, key customers, production processes, and innovative technological solutions. As a result, students developed a comprehensive understanding of how a large international company functions and the important role it plays within the global packaging industry.

Ardagh Group: Global Leadership and Sustainability

Ardagh Group is one of the world’s leading manufacturers of metal packaging for beverages and food products. The company cooperates with many well-known international brands and operates extensive production facilities across numerous countries, which confirms its strong position and global relevance within the packaging market.A key focus of Ardagh Group’s strategy is sustainable development and environmental responsibility. Recycled materials are widely used in production, contributing to resource efficiency and circular economy principles. In addition, the company actively implements measures to reduce CO₂ emissions, optimizes energy consumption, and increasingly relies on renewable energy sources in its manufacturing processes. These initiatives demonstrate Ardagh Group’s commitment to minimizing environmental impact while maintaining high product quality and industrial efficiency.

By combining large-scale industrial production with innovative and sustainable solutions, Ardagh Group plays an important role in shaping the future of metal packaging and supporting the long-term sustainability of the global packaging industry.

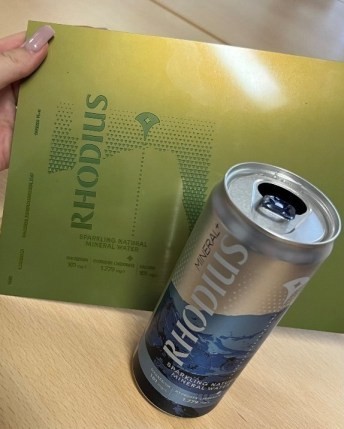

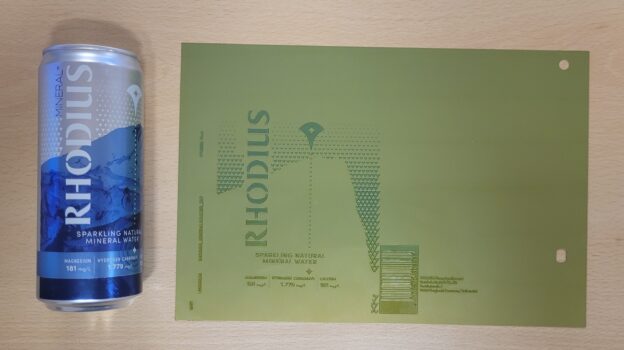

Production, Innovation, and Inspiration

The production facilities made a strong impression through their modern equipment, high level of automation, and extensive use of robotics. Manufacturing processes are carried out with exceptional precision and speed, ensuring consistent product quality while maintaining high levels of efficiency. Ardagh Group continuously invests in innovative technologies and systematically optimizes its production processes in response to evolving market and sustainability requirements.In addition to technological excellence, the company places strong emphasis on employee well-being. Safe working conditions, a well-organized and comfortable working environment, and opportunities for professional growth and skills development form an integral part of Ardagh Group’s corporate culture. This holistic approach to industrial production highlights the importance of human capital alongside automation and digitalization.

For the students, the visit became a significant source of inspiration and motivation. It clearly demonstrated how innovation, environmental responsibility, and effective management can be successfully integrated within a large industrial enterprise. The experience encouraged students to reflect on their future professional paths and reinforced the idea that modern industry offers meaningful opportunities to contribute to sustainable development and responsible technological progress.